As a premier magnetic level gauge manufacturer based in Baton Rouge, Louisiana, Jogler, LLC provides safe, economical, and reliable solutions for measuring and controlling liquid levels across a wide range of process pressures, temperatures, and fluids.

Our high-quality magnetic level gauges are engineered for precision and durability, serving critical applications throughout the USA and globally. Each component is designed to ensure dependable, maintenance-free operation, meeting the stringent demands of modern industrial environments.

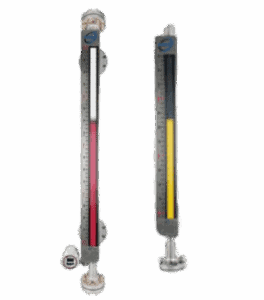

High-Performance Magnetic Gauges

Jogler’s magnetic level gauges are custom-engineered to meet exact customer specifications. We offer a variety of materials, including 316/304 SS, Hastelloy C, CPVC, Inconel, and Titanium, to handle diverse process fluids and conditions.

Our products are designed to comply with ASME B31.1 and B31.3 standards, providing robust performance from full vacuum to 5,000 PSIG and temperatures ranging from -320°F to 1,000°F. These ASME-compliant magnetic level gauges deliver the reliability required by critical industries.

Key Features and Engineering Excellence

- Extruded Outlets: We utilize extruded outlets on our chambers to ensure smooth, reliable float travel. This advanced manufacturing process allows for full-bore connections, eliminating chamber distortion and internal protrusions that can impede float movement. Jogler offers superior extruded outlet level gauges.

- Deep-Drawn Floats: To reduce the potential for stress cracking and failure, our floats are constructed from deep-drawn halves, minimizing welds. This seamless design enhances the durability and longevity of our magnetic gauges.

- Optimized Magnetic Coupling: Our design features an optimized magnetic circuit that ensures a strong, reliable coupling between the internal float and the external indicator, even through thick chamber walls.

- Durable Indicator Construction: Jogler’s unique two-piece flag rail design prevents temperature-related distortion and breakage, ensuring clear and consistent level indication.

Applications Across Key Gulf Coast and International Industries

Our magnetic gauges are extensively used in demanding environments for oil & gas, chemical, power, and other industries.

Centrally located in Louisiana, we are positioned to serve the core of the Gulf Coast’s industrial sector, including petrochemical, manufacturing, power generation, and pulp and paper processing facilities, both across the Gulf South and around the globe.

Product Categories

Explore our specific product offerings to find the ideal solution for your application.

Single or Dual Chamber (JMG) Level Gauges

The JMG series is designed for maximum flexibility and can be customized with various components and materials. These magnetic level gauges provide a revolutionary measurement solution tailored to your specific process requirements.

External Chambers (JXC)

JXC External Chambers are custom-configurable ASME-compliant pressure vessels designed for use with a variety of instruments, including magnetostrictive level transmitters, guided wave radars, and capacitance probes.